Role of Laboratory in Precision Feeding

- Innovation

Since the mid-1950s, the pace and scale of environmental change has grown exponentially. Food production is one of the largest source of environmental degradation. To be sustainable, food production must occur within food-related planetary boundaries for climate change, biodiversity loss, land and water use. However, production must also be sustainably intensified to meet the global population's growing food demands.

Growing world population, urbanization, a growing middle class and changing diets will lead to a surge in demand for fish and meat, especially in emerging markets. Of course, this brings opportunities for the feed industry to grow its business. However, as mentioned before sustainability is an issue. Hindrance to sustainability include scarcity of resources, food safety, animal welfare, antibiotic resistance, pollution, climate change and loss of biodiversity. In addition, we must cope with volatile commodity prices, as supply and demand fluctuate, and with unbalanced cost/price distributions in the value chain.

Precision Feeding

Precision feeding is an information-technology derived nutritional feeding solution to feed the nutrient requirements of animals as accurately as possible in the interest of safe, high quality and efficient production, while ensuring the lowest possible load on environment. Precision feeding involves a multi-disciplinary integrated approach.

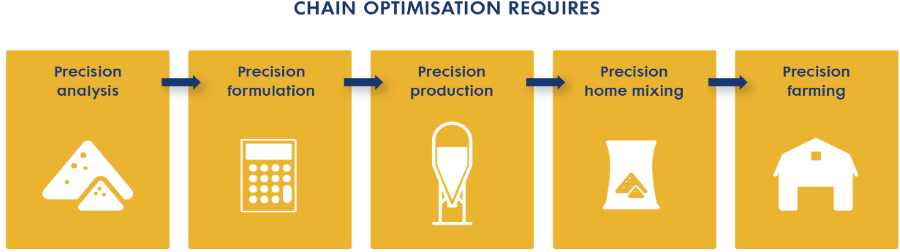

For practical achievement of precision feeding, precision needs to be followed in every step of the production process, as shown in Fig. 1 below:

Fig. 1: Requirement of precision in every step

As detailed above, the primary requisition for precision feeding is the precise estimation of nutrients available in the raw materials to be included in the feed (quality control techniques) followed by precise ration formulation on available nutrient basis.

Precision analysis – role of laboratory

The nutrient analysis of raw materials involves basic proximate principles, soluble protein, amino acid composition, vitamin and mineral content, anti-nutrition factors (ANFs) if any, non-starch polysaccharides (NSPs) etc.

Wet Chemistry analysis

Traditional wet chemical analysis are still employed in our country for proximate analysis. Although traditional analysis provide valuable information, most of them are time consuming, laborious and expensive. Many a times, the analytical results might be available after the batch/lot has been consumed. Also, the number of samples that can be analyzed in a given time (frequency) is relatively lesser. Additionally, the cost involved for maintaining a traditional laboratory is generally higher.

Near-infrared reflectance Spectroscopy

A new technology and fairly established concept is “Near-infrared reflectance spectroscopy (NIRS)”. NIRS is based on light absorption at near-infrared wavelengths by molecules constituting the sample, in a non-destructive, rapid and predictive technique. NIRS is one of the most suitable approaches for online quality control of nutritional analysis. Thus, NIRS is an efficient first-line screening tool for monitoring the quality and safety of feed protein materials. The output (analytical results) obtained from NIR is highly dependent on the input being fed, the input here being the wide range of wet chemistry analysis of the various nutrients of raw materials. The more the variability of the inputs, better will be the accuracy of the output expected. The amount of database available, the maintenance of calibrations, and the norms followed for calibrations, validation, etc. influence the accuracy of the results obtained from usage of NIR in field conditions.

In many a cases, commercial NIRS is used to provide the basic proximate analysis of raw materials/finished feed, whereas a detailed extended nutrient analysis in terms of the amino acids, metabolizable energy, ANFs etc. are also crucial in feeding precise nutrients to animals. These extended nutrients should by far be dynamic species-specific equations so as to have real time values.

Conclusions

Feeding of animals in an optimal way needs the supply of a diet balanced in all nutrients and free from deleterious components. The nutrients provided should meet the production objective and animal products produced should be safe for human consumption. The availability of accurate, reliable and reproducible analytical data is imperative for proper feed formulation and is the essence of precision feeding. Therefore, the laboratory involved in generating this analytical data, must be quick enough to produce this data, to support precision feeding. In order to achieve this, the laboratory must adopt newer technologies like NIRs.

NutriOpt

As one of the leading feed solutions experts, Trouw Nutrition has set itself the mission of addressing the above challenge. This means making the actual, rather than theoretical, nutritional values of feedstuffs known, judging whether tested feed samples meet optimal quality standards, and advising on any modifications to be made to a diet. Trouw is making this possible via its NutriOpt program, which is modular, precision-feeding system designed to optimize chain profitability by connecting animal performance with the cost benefit ratio of supply and demand through precise real-time modelling and analysis. One of the verticals of the NutriOpt is NIR measurements, which boasts of huge numbers of calibration lines. This combined with extensive database and advanced prediction modules enable the user to fine tune the feeding strategy for poultry and ruminants.

NutriOpt On-site Adviser (NOA)

In order to increase the efficiency of NutriOpt platform, Trouw Nutrition also launched a novel product called NutriOpt On-site Adviser (NOA). NOA is a small portable NIRS instrument connected to NutriOpt platform via smart phone interphase. Being handy, NOA acts as a concept of “bringing the lab to the sample”. It allows customers to perform accurate on-site analysis of raw materials and provides instant report of results comprising of the proximate and extended nutrients (amino acids, energy, fatty acid etc.). NOA utilizes the power of thousands of calibrated data points from within the NutriOpt nutritional database to provide all quality nutritional solutions instantly and enabling the customer to make better-informed decisions in the day-to-day use of feedstuffs, in a quicker way.

Please get in touch with your local Trouw Nutrition representative for more information on NutriOpt and NOA or contact us at customercareindia@trouwnutrition.com